How the Direct Store Delivery Model Works for Fast-Moving Goods?

Direct Store Delivery (DSD) is a supply chain model where manufacturers or suppliers deliver goods directly to retail outlets, bypassing traditional distribution centers or warehouses. The DSD model is commonly used in the fast-moving consumer goods (FMCG) industry, particularly for products that sell quickly, are perishable or have a short shelf life, and are purchased frequently. This includes items like snacks, soft drinks and bottled beverages, bread and other baked goods, and milk, cheese, and other dairy products.

Here are the key steps involved in the DSD process:

- Order Placement: Retailers place orders directly with manufacturers or suppliers, usually via electronic systems, allowing real-time communication of demand and streamlining order processing.

- Product Picking and Packing: The supplier is responsible for selecting the correct products based on the retailer’s specifications and packing them securely before delivery directly to the store. Special care is taken for perishable or fragile products to maintain quality and minimise damage.

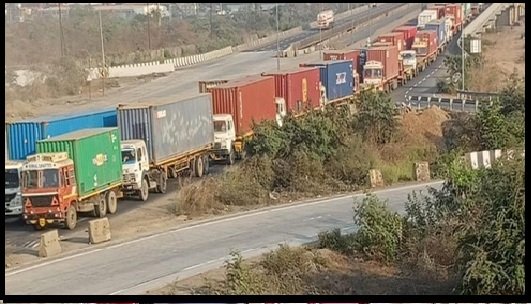

- Direct Delivery to Store: Products are loaded onto delivery vehicles (often company-owned) and transported straight to retail stores, bypassing any intermediate warehouse or distribution center.

- In-Store Merchandising (often in FMCG): Upon delivery, supplier representatives frequently assist with stocking shelves, managing product displays, and even organising promotional materials. It can help you increase product visibility and achieve optimal shelf conditions.

- Invoice and Payment Processing: The invoicing process is often handled electronically at the time of delivery, maintaining accurate records and reducing administrative overhead.

Now, let’s look at some reasons why DSD is used for fast-moving goods.

- Immediate Restocking: DSD enables manufacturers to rapidly replenish stock, minimising shelf gaps and quickly responding to spikes in consumer demand. It’s an important factor for perishable and high-turnover items.

- Enhanced Product Freshness & Quality: Direct shipments reduce the time products spend in transit or storage, ensuring maximum freshness and minimising spoilage, especially for items with a short shelf life like dairy, bread, and produce.

- Reduced Handling Risks: DSD reduces how many times a product is handled between the manufacturer and the store. Since there are fewer steps and less handling, there’s a lower chance that items will get damaged, lost, or mishandled. This is especially important for fragile products like glass bottles, perishables, or electronics.

- Operational Efficiency & Lower Costs: The DSD model reduces labour and storage costs for retailers by eliminating the intermediate warehousing stage and often delegating replenishment and merchandising to the supplier’s team.

- Improved Inventory Management: Real-time communication and direct delivery allow for more accurate inventory tracking, reducing the risk of overstocking or stockouts and offering greater responsiveness to market trends.

Common product categories that benefit from DSD:

| Product Category | Rationale for DSD |

| Snacks & Beverages | High turnover, need for freshness, frequent restocking |

| Dairy & Bakery | Perishable, require temperature control, short shelf life |

| Produce/Flowers | Extremely perishable, require gentle handling and rapid replenishment |

| Frozen Foods | Temperature controls, frequent store visits needed |

| Household Items | High-frequency purchase, frequent promotions |

Direct store delivery is the preferred model in distribution management for fast-moving and perishable goods because it ensures products reach the shelves faster, fresher, and more efficiently. It streamlines supply chains, reduces costs, enhances inventory turnover, and provides significant value to both retailers and manufacturers in the competitive FMCG sector.